My dad passed away last year on the last day of March. He accomplished many of the things he wanted to do in life and he was much loved. Can you do much better than that? He was a man of many interests. One that he retained and cultivated his whole life, was woodworking. He also loved music, taking up the violin when he was 13 and putting it down pretty soon after. Still, he continued to enjoy listening to classical music for most of his days, and as a septuagenarian dove in once again to both the violin, and then the viola. When you combine an early interest in violin, with a life-long interest in woodworking, it must be inevitable that one day you will wish to build one, and so it was with my him. Yet he was nothing if not methodical, so he conceived a plan, a graded plan in woodworking projects to culminate with making a violin.

First he would build a guitar. A pretty complex project to be sure, but simpler than a violin: the back and top are flat and the curves of the sides are relatively mild. Next up would be a viol da gamba. When he conceived this plan back in the early 1970’s, the viol da gamba was a pretty obscure Baroque era instrument. With a resurgence in period instrument practice in the years since, it’s still a pretty obscure instrument, but somewhat less so. Anyhow, the viol da gamba is outwardly much like a cello, though it derives from the lute family of instruments. Most importantly for my father’s plan, it shares a similar construction to the violin family, but only the top is carved. The back is flat and the scroll gracing the top of the neck can be somewhat simplified and still be considered traditional — so, a step up in complexity from the guitar. Finally, after getting through both of those instruments, he would tackle a violin.

He was nearing 50 when he began building his guitar. In less than a year of casual nights and occasional weekends the instrument had taken form but it wasn’t quite completed (his day job as a professor, playing Mr. Fixit to an old house, along with being married and father to 3 kids took some time too). Many things intervened and months passed. Then years came and went, but the guitar remained unfinished.

I entered my teenage years during this time and at some point got bitten by the guitar playing bug, so the pestering began: “when are you going to finish the guitar, Dad?” I hate to think how many times I repeated that obnoxious mantra, but to no effect anyhow. The guitar was on hold.

The early 1980’s saw a big lifestyle change for my folks, from city dwellers to country folk as they moved to a 100 acres of land, and not a whole lot else, in rural West Virginia. I was off in college then, coming back in the summers to lend a hand where needed. As the days of one summer passed, a plan of my own began to emerge. Really, more of a feeble stratagem to compel my dad to finish that guitar: I would start one myself and maybe that would get him jump-started if I began to make some progress!

I deemed this possible as he had already made all the complicated jigs and forms, there was a nice stash of wood he had collected, there was a bit of a wood-shop up and running, there was the book he had used, and most of all, there was him to help me. As it was, I was unskilled at woodworking. My dad, however, was widely read, had tackled a variety of complicated projects, was meticulous, and skilled with hand-tools. It’s true, I had carved a dish out of mahogany in high school wood shop (I was pretty proud of the blue velvety flocking applied to the bottom) and Dad had taught me how to drill a pilot hole and countersink prior to driving a screw, but really, I had no business starting in on building an acoustic guitar.

Well, my sad attempt to inspire my dad did not come to fruition in the time frame I envisioned — it was over a decade later before his guitar sounded its first notes. But once I got rolling on my guitar, the thing took on a life of its own. I was absolutely consumed with the project and spent all my available hours on it. By the end of the summer I was playing on the guitar I had built. It wasn’t very pretty, but I was kind of amazed that I managed to get the thing together at all and it actually played and sounded pretty good. More importantly for my future, I had finally found an endeavor that had lit my passion. I knew from that point on that I wanted to be involved in fine woodworking.

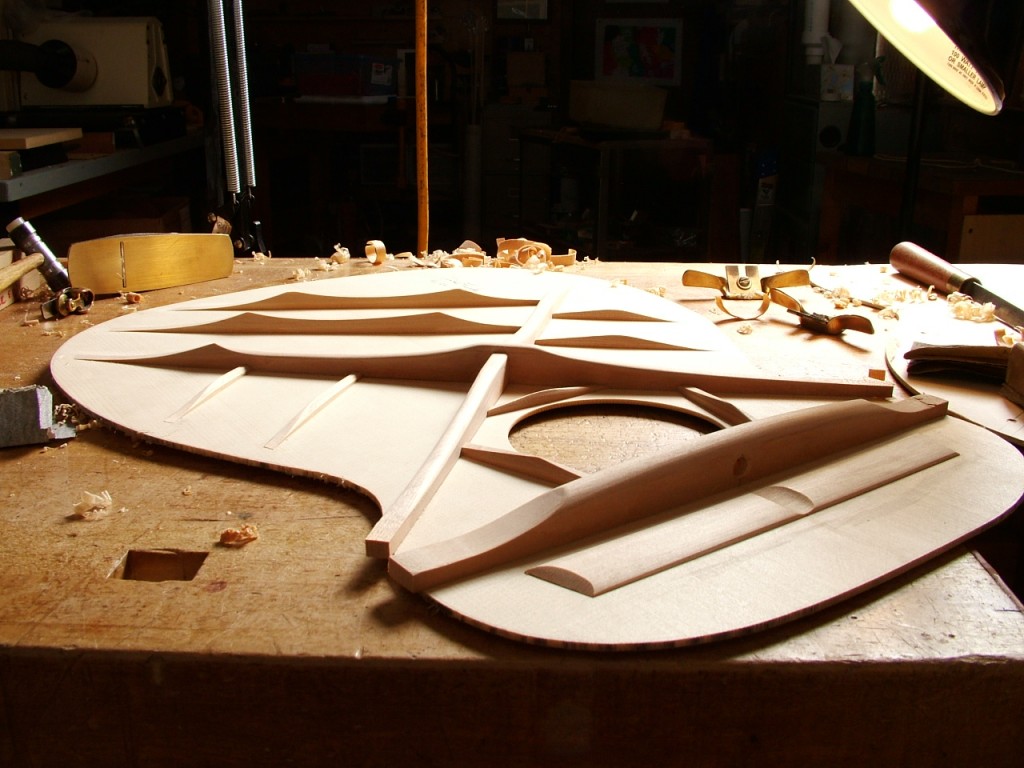

And what of my dad’s plans to build a violin? In the ensuing years, with his guitar finally completed, he moved on to phase two, the viol da gamba. Again, he made good progress in year one, but again, life intervened with many other demands on his time. Years passed, his health went into decline, and finally, he passed away with the viol uncompleted and the dream of building a violin unrealized.

It was around the time his guitar was finally completed that my wife and I had our first daughter, followed two years later by our second. When they were very young (two and four) I got the idea that it would be a good thing to start them playing violin. Fourteen years later, they are both superb musicians.

When my dad died I inherited some specialized violin making tools: calipers, finger planes, reamers, and many books on the topic. I also inherited a partially built viol da gamba.

I knew I needed to complete his viol da gamba, but only recently did it occur to me that it was also time for me to pickup the gauntlet and complete the violin project he began forty years ago. This winter I’m planning to build a couple of violins. They’ll be for my daughters. I’ll be thinking of my dad while I work: many fond reminiscences, beginnings and endings, dreams only dreamt and dreams realized. The outlook ahead is for a nice, warm, winter. I’ll keep you posted .

.

Until next time,

df

generates insights and reveals nuances that reading alone cannot fully convey. Mr.

generates insights and reveals nuances that reading alone cannot fully convey. Mr.